MACHINERY FOR THE TEXTILE INDUSTRY

Our company manufactures oval-shaped tubs for dyeing packaged wool garments, drum tubs for dyeing of ready-made cotton garments, tubs with arm system for dyeing of yarns in banks, tube equipment for dyeing of yarn bobbins, colour kitchens for the dosing of products in dyeing machinery, felting machines for acrylic fabrics, laboratory equipment, dyeing accessories, tubs for dyeing of patterned fabrics, tumbler for garments aging, ecofarben for dyeing of delicate garments, obermayer for flock dyeing and special executions in stainless steel.

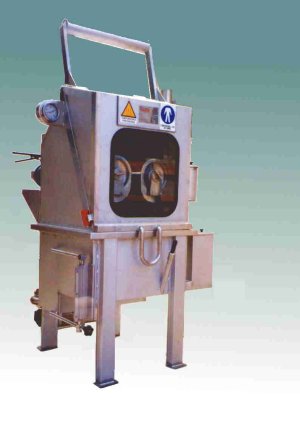

ECOFARBEN

ECOFARBEN stems from a special need that, for over twenty years, has characterised all the innovations made to the dyeing machinery: decreasing the amount of water needed to dye a kilogram of material (liquor ratio).

To date, no innovation has been made in the dyeing industry for the ready-made cotton garments (knitwear, shirts, trousers, hosiery, scarves, gloves, hats, etc.).

"ECOFARBEN" has reduced the liquor-ratio from 1-35 to 1-15 because, unlike the traditional tubs called "OLANDESI" (Dutch) - within which all garments are introduced individually- garments are actually collected in a drum and do not require the excessive amount of water used up to now: the spinning movement of the drum vigorously shakes the garments, guaranteeing a proper treatment and a perfect dyeing.

"ECOFARBEN" allows a considerable saving of time for loading and unloading and a liquor-ratio decreased by more than half; it also guarantees water savings when drawing, heating, purifying and permits to reuse the rinsing water for the next dyeing.

"ECOFARBEN" allows to dye all those cotton garments which have always been processed on special machinery equipped with rotating drums, called "LAVA-CENTRIFUGA"(wash and spin): such machines are able to provide the same dyeing results but are also really expansive and suitable only for a specific type of treatment: "ECOFARBEN" can be pressurized thus reaching a temperature of 108 ° C and allowing to dye garments made from synthetic fibres that have always been processed on yarn- dyed, a treatment that involves great waste and unusable yarn left.

Another great advantage lies in the possibility to have different dyeing capacities with the same machine, thanks to high drums of different sizes. This is possible just by changing the drum and maintaining the liquor ratio unchanged; moreover, it is easy to install as “ECOFARBEN” does not require any foundation as it can be placed directly on the floor and the hole for the centrifuge drum on the front of the machine is not necessary, as the unloading occurs on a raised floor.

A further advantage is certainly the possibility of automation offered by this machine, providing capacity to automatically load and unload the drum, thus to make "ECOFARBEN" a leading product in the dyeing industry for ready-made garments.

OBERMAJER

per tintura fibre tessili in fiocco

Machines built entirely in AISI 316 stainless steel in the models from 1 kg to 900 kg wool base and built as follows.

Support base, dyeing autoclave, perforated inner drum, material holder, pressing cap, lid with pneumatic opening, high-flow pump with suction and delivery pipes, dye introduction container with related accessories, power panel with inverter, programmer and EC mark.

OVAL TANK FOR DYEING FABRICS

It is made up of stainless stell AISI 316 in versions from 1 kg to 300 kg of wool base. The machine consist of the following component parts: machine body with central isolated part, indirect steam heating coil, total cover with doors for loading and unloading operations, dye tank, shaped light duty lathe, drive motor 3-30 rpm, thermometer, control panel with inverter, rapid unloading hatch, programmer, EC mark.

DYEING ARM TANK FOR SKEIN YARNS

It is made of stainless steel AISI 316 and it is constructed in version with one arm L=300, L=500 or L=1000 and two arms L=500 or L=1000 (arm L=1000 dyeing capacity 5 kg of wool base). It can operate at 97 degrees and it is made up of the following components : dyeing tank, double effect serpentine, flow adjusting valves, reflux valves, level indicator, thermometer, centrifugal pump, tubes, dyeing arms, sampler, electric panel, programmer and EC mark.

TANK FOR PATTERNED MATERIAL DYEING

This machine is entirely made of stainless steel AISI 316. It is constructed in several version for dyeing 50, 100, 150, 200, plies other than various knitwear items, scarfs, gloves, hats and cloth.

It is composted of a dyeing thank and a rinsing thank; front and rear low-high overhead crane with self-braking motors, double trolleys supports, control panel with automatic-manual keyboard, heating serpentines, trolley cage, thermometer, filling valves, overflow indicators, connection for programming probe, dye infeed tank, EC mark.

LABORATORY DEVICE TYPE BAIN-MARIE

It is made up of stainless stell AISI 316 in versions with 2-12 glasses from 200cc to 600cc. The machine is composted of the following component parts: big case, dyeing glasses with relevant material supports, hating resistance, control pneumatic part, electric panel with timer and thermostat, EC mark.

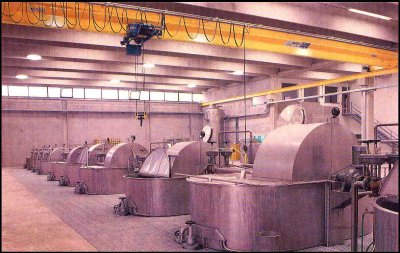

DRUM TANK FOR DYEING CLOTHS

It is made up of stainless stell AISI 316 in versions from 1 kg to 50 kg of cotton base. The machine is composed of the following component parts: machine body with internal drum, indirect steam coil, upper cover, dye tank, 3-30 rpm drive motor, thermometer, control panel with inverter, programmer, EC mark.

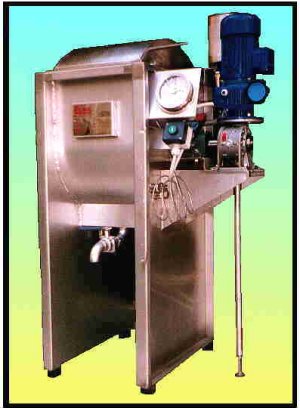

COLOUR LABORATORIES

Colour laboratories are made of stainless steel AISI 316 and they are built in models of 50-100-200-300-400-500-600-1000 litres. They are used to prepare products to be sent to dyeing machines and their component parts are listed in the following : cylindrical container with conical bottom and supporting feet, tube holed in its upper side used for filling and rising operations, filter, control panel, programmer, connecting pipes provided with an exhaust valve, EC mark.

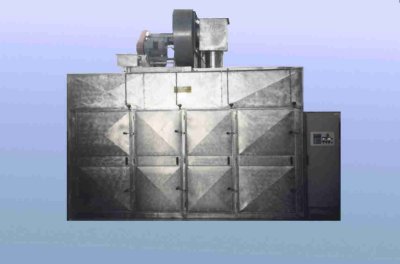

FELTING MACHINE FOR ACRYLIC FABRICS

This machine is entirely made of stainless steel AISI 304. It is constructed in version with three and four sections with a diameter equal to 2500x1000. It is particularly suitable for steaming, ageing and treating pile acrylic, woolly, suede and lapped fabrics along with imitation leathers. The felting machine is composed of the following component part: external insulated paneling whose panels are fitted with loading and unloading doors, cooling panels, revolving basket divided in section, basket drive, steam coils, heating batteries, air fan, exhauster, control panel, programmer, EC mark.

DYEING TUBE SYSTEM FOR CONE YARNS, FLOCKS AND PIECE GOODS

It is entirely made of stainless steel AISI 316 and it has been exempted from ISPESL control. It is constructed in versions with one , two, four, six and ten tubes (5 kg of wool for each tube). This machine can work at 4 BAR and 145 degrees. It is made up of the following component parts : supporting structure, dyeing tubes, pipings, valves, double effect exchanger, centrifugal pump, static pump, bath shifter, thermometer, pressure gauges, dye tank, sampler, electric panel, programmer EC mark.

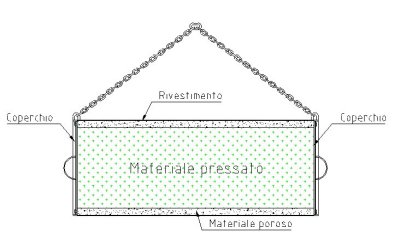

TUBE FOR BADLY DYED FABRICS

Tube Ø 400x1000 Kg. 10 wool base, Tube Ø 400x500 Kg. 5 wool base, Tube Ø 260x1000 Kg. 6,5 wool base, Tube Ø 260x500 Kg. 3 wool base, Tube Ø 150x1000 Kg. 2 wool base, Tube Ø 150x500 Kg. 1 wool base.

Tube for badly dyed fabrics, made of porous material, coated in stainless steel AISI 316, working by immersion with materials pressed inside (garments, fabrics, skeins, etc.).

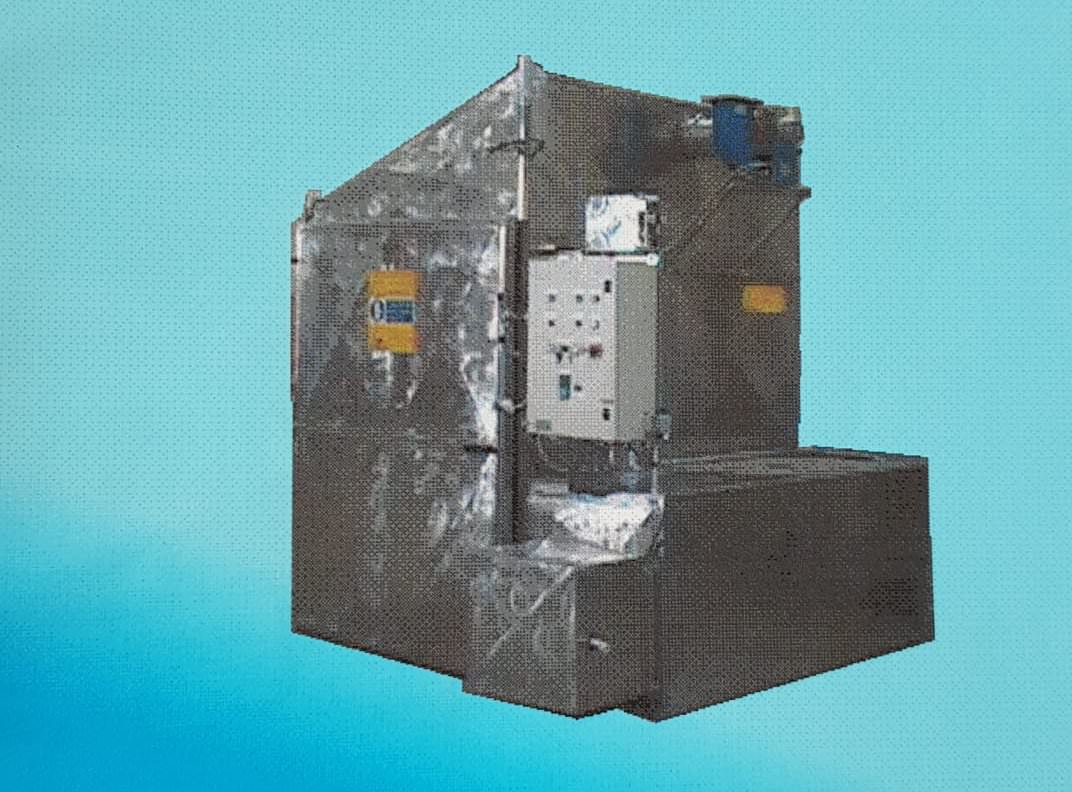

STATIC KILN

It is made up of stainless steel AISI 304. It contains about 100 cloths. lt is particularly suitable for steaming and drying prints on cloths, but it is also suitable for drying a little number of delicate cloths, flocks of textile fibres and skein yarns. The machine is composed of the following component parts: external insulated paneling whose panels are fitted with loading and unloading door, heating with battery or methane burner, air fan, exhauster, 2 material supports trolleys, electric panel with programmer and EC mark.

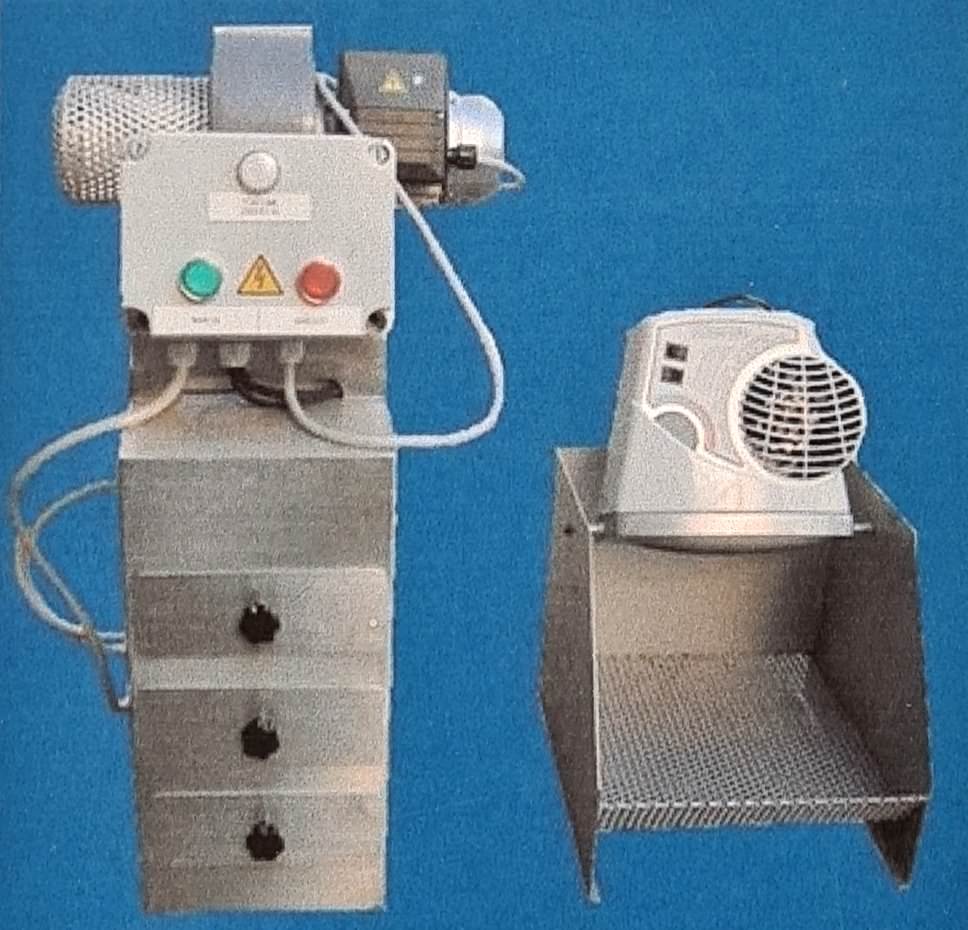

LAB SAMPLES DRYER

They are made up of stainless steel AISI 304 in the three drawers version with resistances of 2000+2000 Watt with ventilator and, in the pierced flat version, with thermo ventilator from 1000+1000 Watt. They are completes of control electric components and carters. They are particularly suitable for drying of all fibres.

TUMBLER FOR TO MAKE LOOK OLDER THE FABRICS

This machine is entirely made of stainless steel AISI 316 in the version of Ø1400x1450 of the basket, it is particularly suitable for ageing fabrics with pumice stone and consists of the following components: insulated supporting structure with loading and unloading doors, cleaning and dismantling, revolving basket with door, basket drive with inverter, electric control panel with timing for left and right rotation of the basket, a micro sensor when the door is opened and a positioning sensor, EC mark.